Key Takeaways

- Frequent PPE replacements drive up operational costs and wreck budget predictability.

- Subpar gear leads to injuries, OSHA violations, and potential legal action.

- Poorly made or uncomfortable PPE slows teams down and hurts productivity.

- Unsafe conditions increase turnover, triggering more recruiting, onboarding, and training expenses.

- Your PPE program directly impacts compliance, morale, and your company’s reputation.

- A Total Cost of Ownership (TCO) approach shows that investing in quality PPE improves ROI over time.

- Involving workers in PPE selection increases compliance, builds trust, and leads to better adoption.

The Illusion of a Bargain

Cheap PPE seems like an easy way to cut costs. For organizations purchasing PPE for many workers, the appeal of lower unit costs is strong. But what looks like cost‑saving at first often hides a much larger expense over time.

Underpriced PPE often uses lower‑quality materials. Standards may be met in name only or only under laboratory conditions, but real jobsite conditions like mud, heat, repeated use, and chemical exposure, stress gear in ways budget models often ignore.

What seems like savings becomes an expense when gear fails, when workers suffer, when you’re replacing items constantly, and when compliance becomes an issue. The math shifts quickly from “cheap purchase” to “expensive gamble.”

The Real Costs of Cheap PPE

1. Frequent Replacements

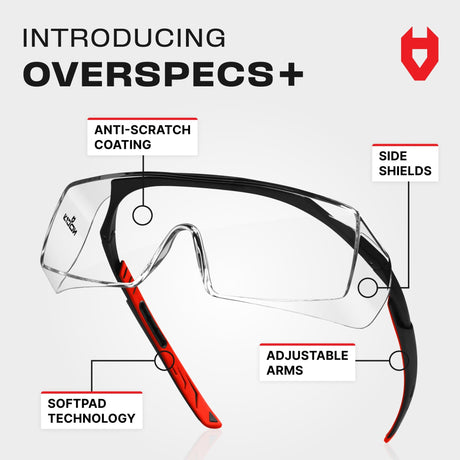

Cheap PPE tends to degrade faster. Stitching can unravel, coatings wear off, lenses get scratched or fogged, straps lose elasticity. Each failure triggers a replacement. Over time, the cost of constantly buying replacements, managing inventory, ordering, shipping, and disposal adds up.

If PPE lasts half as long, you’re buying twice as often. That raises not only material expenditure but also labour hours: admin, inspections, stock management, and waste. It’s not just “more units” but “more problems” every time something breaks.

2. Equipment Failure = Injury Risk

When PPE fails at the worst moment, people pay, and so does your company. Gloves tear, face shields crack, respirators leak. These failures expose workers to cuts, chemical burns, inhalation hazards, or severe impact.

Studies show that PPE failures risk not just injury but also costly health incidents. The National Safety Council pegs the average cost of a medically consulted injury in the U.S. at over $42,000, counting medical expenses, lost wages, and administrative costs.

Even if you avoid a big accident, minor injuries accumulate: small cuts, eye irritations, skin abrasions. Those lead to downtime, morale loss, and potential workers’ compensation claims.

3. OSHA Violations and Legal Exposure

Regulatory bodies don’t reward penny‑pinching on safety. OSHA in the U.S. requires employers to provide many forms of PPE at no cost.

Penalties for serious violations can be over $16,550 per violation as of 2025. Willful or repeated violations can run to $165,514 per violation.

If cheap PPE fails to meet standards, or doesn’t get maintained or replaced, fines are only the start. Legal exposure may include personal injury suits, reputational costs, and increased insurance premiums.

4. Productivity Loss and Downtime

Even when gear doesn’t fail catastrophically, it can slow people down. Poor fit, excessive weight, uncomfortable weight distribution, heat retention, noise, restricted movement, all reduce efficiency.

One recent study found that PPE can negatively affect cognitive load, communication, task efficiency, and fatigue among health professionals. For example, hearing muffled, vision partially obscured, or feeling physically constrained can slow reaction times or increase error rates.

The longer breaks, slower task completion, or even small delays to adjust gear or fix foggy lenses accumulate into a meaningful loss in output and schedule delays. Multiply that across teams and projects, and the loss grows.

5. High Turnover and Hiring Costs

Uncomfortable or unsafe working conditions lead to employee dissatisfaction. Workers notice when PPE is inadequate or causes discomfort. That contributes to turnover.

Replacing skilled staff isn’t cheap. Hiring, training, and getting new people up to speed takes time and money. While exact figures vary by industry, it’s common to see replacing one skilled worker costing tens of percent of salary plus loss of productivity during onboarding.

Turnover also erodes institutional knowledge. As pushes to save on PPE lead to turnover, you lose people who know jobsite tricks, safety insights, best practices: things cheap gear never compensates for.

6. Training Burden

Every new or replacement worker must be trained on how to use PPE correctly, how to inspect it, how to report damages, how to maintain it. More replacements and more injuries mean more training cycles.

Mistakes in how PPE is worn are often connected to inadequately trained personnel. Training takes supervisor time, takes focus away from other safety or production issues. Frequent rehiring multiplies this cost.

7. Damage to Brand and Reputation

Safety incidents are visible. News, social media, insurance claims can publicize failures. Clients also look after their safety reputations; they prefer working with companies that treat safety seriously.

A company known for corners being cut may lose contracts, find it harder to recruit or retain skilled workers, suffer increased inspections or oversight. Reputation repair is slow and often more costly than prevention.

What About The Human Factor?

Every PPE decision affects real lives.

Discomfort isn’t trivial: long hours in ill‑fitting gear cause fatigue, skin damage, restricted motion. Mistakes increase because people are more focused on discomfort or adjusting gear than on tasks.

There is psychological cost too. Workers who feel unsafe may experience anxiety, stress, frustration. Communication can suffer; if respirators muffle speech, or gloves reduce dexterity, teamwork suffers. There may even be long‑term mistrust: when workers perceive that safety is treated like a low priority, morale drops.

In the mixed‑methods study of health professionals mentioned above, respondents reported that PPE reduced their ability to do tasks efficiently, caused fatigue and discomfort, and hampered communication.

Also, poorly‑fitting gear slows reaction time and reduces mobility. In one paper, participants using ill‑sized or poorly designed PPE showed decreased endurance, slower response, and greater discomfort.

These are not side issues; they directly influence safety, error rates, and how likely workers are to wear gear correctly.

Building a Smarter Cost‑Benefit Analysis

Making the right call on PPE starts with asking the right questions. What are your real risks? What will the gear actually cost over time? What benefits does it bring? And how does cheap gear really stack up against quality options?

Follow these four steps (identify risks, calculate total cost of ownership, quantify benefits, and compare ROI) to make decisions that protect both your crew and your bottom line.

Step 1: Identify Your Real Risks

- Conduct a detailed hazard analysis: list tasks, substances, environmental conditions, exposure times.

- Consult applicable legal/regulatory standards (OSHA, ANSI, EN, etc.) and internal policies.

- Engage workers: ask what gear fails and what complaints are common.

Step 2: Calculate Total Cost of Ownership (TCO)

Include:

- Initial purchase cost

- Expected useful life (how many uses, exposure cycles)

- Maintenance, cleaning, repair

- Replacement frequency and stock‑outs

- Safety‑incident costs: medical, compensation, liability

- Productivity costs: time lost adjusting or replacing gear, error rates

- Turnover and training costs

- Reputational and compliance costs (fines, reputational damage)

Step 3: Quantify Benefits

Use data:

- Compare incident/near‑miss rates before and after upgrading PPE

- Measure how many units used per year vs the expected lifespan

- Track worker feedback on comfort, fatigue, ease of use

- Survey time lost or speed reduction due to gear issues

- Monitor retention rates or absenteeism

Step 4: Compare ROI – Cheap vs. Quality PPE

Once you’ve mapped out your risks and costs, it’s time to put the numbers to work. You’re not just comparing price tags, you’re comparing outcomes.

Let’s say you’re choosing between two types of safety gloves for a 50-person crew. Option A is $4 a pair and lasts one week. Option B is $12 and lasts a full month under the same work conditions.

Over three months, you’ll need:

- Option A (cheap): 12 pairs per worker × 50 workers = 600 pairs → $2,400

- Option B (quality): 3 pairs per worker × 50 workers = 150 pairs → $1,800

That’s already $600 saved just in glove purchases.

Now factor in the hidden costs. One minor hand injury from a torn glove could cost $10,000 in workers’ comp, lost time, and medical bills. Let’s say cheap gloves lead to just two injuries a year. That’s $20,000 in preventable costs.

Add in time spent replacing gear, managing stock, and onboarding new hires due to discomfort or safety concerns. Say your turnover drops by just 10% because people feel safer and more valued; that alone could save $25,000–$50,000 a year in recruiting and training costs.

All in, your “expensive” gloves could save $45,000–$70,000+ per year, depending on the size of your team and the environment they work in.

And that’s just gloves. Now imagine applying that same logic across eyewear, respirators, coveralls, kneepads, boots, and more.

The longer you stretch the lens (six months, a year, three years), the more obvious the payoff becomes. Premium PPE isn’t a cost. It’s an investment in safety, productivity, and the bottom line.

Conclusion

Cheap PPE can seem appealing, and in certain low‑risk cases, it might get the job done for a while. But if you’re running real operations, especially with many workers, harsh conditions, or regulatory oversight, the risks stack too high.

Investing in good PPE isn’t merely about compliance or avoiding fines—it’s about protecting people, maintaining consistent performance, retaining your workforce, and preserving reputation. When you count all the hidden costs (medical, legal, downtime, turnover, morale) the cheaper gear often ends up being the more expensive gamble.

In the end, quality PPE is an investment in safety and profitability. It pays off in fewer failures, injuries, better compliance, stronger teams, and less drama.

For any organization serious about long‑term performance, the question should not be “Can we afford good gear?” but “Can we afford not to invest in it?”

FAQ

Why is cheap PPE more expensive in the long run?

Because it doesn’t last. You end up replacing it more often, which adds up fast, especially when you’re buying for a team. Plus, you’re spending time and money on reorders, inventory management, and downtime when gear fails. And when that happens, it’s not just inconvenient, it’s risky. Injuries go up. Morale goes down. People leave for places that take safety seriously. It’s not just a higher bill: it’s a constant drain on time, safety, and reputation.

Can poor PPE really lead to legal trouble?

Yes, and it doesn’t take much. OSHA fines for non-compliance can hit over $16K per violation, and over $165K for repeated offenses. If someone gets hurt and the gear didn’t meet standards? You’re looking at legal exposure, lawsuits, rising insurance costs, and a reputation hit that’s tough to recover from.

How can low-quality PPE lead to workplace injuries?

Cheap PPE often fails when you need it most. A torn glove or cracked face shield might seem minor, until someone gets cut, burned, or worse. Even small issues like foggy lenses or uncomfortable straps can cause distractions and mistakes. Injuries cost more than medical bills; they bring lost time, workers’ comp claims, and shaken confidence.

What’s the impact of bad PPE on productivity?

If it slows your crew down, it’s costing you. Cheap gear often fits poorly, restricts movement, or causes discomfort, leading to more breaks, slower work, and distractions on the job. Multiply that across a full team and project timeline, and you’re losing real time and money every day.

How does PPE quality affect employee retention?

Workers notice when companies cut corners on safety. Uncomfortable or unreliable PPE can drive people to quit, especially in tough or hazardous environments. High turnover means more time spent hiring, training, and losing tribal knowledge. Good gear helps build trust, and helps you keep the people who know what they’re doing.

Why use a cost‑benefit analysis when choosing PPE?

Because price alone doesn’t tell the whole story. A real analysis shows how gear performs over time, factoring in durability, replacement rates, injury risk, and downtime. It helps you compare true costs, not just shelf prices. When you look at the full picture, quality PPE almost always pays off.