Key Takeaways

- Employers are responsible for providing, training, and maintaining PPE use on the job.

- Proper fit and regular inspection are just as important as wearing the gear.

- Training should be specific to tasks and updated when duties, tools, or hazards change.

- Workers need to know not just what to wear, but why it matters.

Every job site has rules. However, when it comes to personal protective equipment (PPE), a printed policy or quick reminder isn’t enough. If your employees don’t understand how and when to use PPE and why it matters, compliance slips. Injuries happen. And accountability lands squarely on the employer.

This guide walks you through everything you need to know about PPE training: what it is, who’s responsible for it, how to ensure gear fits, and what to say during an actual training session. It also includes a free, ready-to-use script that you can adapt for toolbox talks, safety meetings, or onboarding sessions.

What Is PPE?

If you somehow stumbled across this without knowing, PPE stands for Personal Protective Equipment. It’s the gear designed to protect workers from serious injuries or illnesses caused by contact with workplace hazards.

This includes:

- Head protection, like hard hats

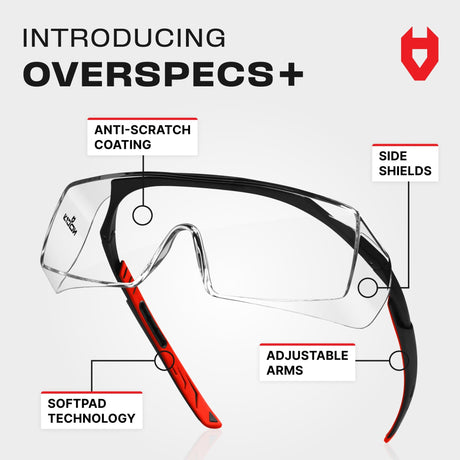

- Eye and face protection, like safety glasses and shields

- Hand protection, such as cut-resistant gloves

- Respiratory protection, including N95 masks and respirators

- Hearing protection like earmuffs or plugs

- Knee and foot protection, like knee pads

PPE acts as a last line of defense. When other controls can’t eliminate the hazard, PPE steps in to reduce exposure.

Safety equipment minimizes the damage when safety systems fall short. It’s not just a checklist item, it’s a critical part of workplace safety planning and culture. And to work, it has to be used properly.

Where Is PPE Needed?

Not every workplace needs PPE, but any place with real hazards does. If there’s a chance of falling debris, flying sparks, sharp tools, chemical exposure, or repetitive impact, OSHA expects you to have PPE in place and a plan to train your crew to use it.

Here’s a few industries where PPE is commonly required:

- Construction sites: Hard hats, safety glasses, gloves, hearing protection, and fall protection

- Manufacturing and fabrication shops: Face shields, cut-resistant gloves, steel-toe boots, respirators

- Warehouses and distribution centers: High-visibility clothing, back support belts, gloves

- Chemical plants and labs: Protective suits, goggles, gloves, ventilation masks

- Medical and dental facilities: Gloves, masks, gowns, face shields

- Landscaping and groundskeeping: Eye and ear protection, gloves, long sleeves, kneepads

- Welding and metalwork: Helmets with appropriate lenses, gloves, flame-resistant clothing

For anyone finding per diem construction work, PPE is especially important. These roles often involve moving between active job sites, where OSHA safety requirements apply from day one.

What Does OSHA Require?

According to the Occupational Safety and Health Administration (OSHA), employers must:

- Assess the workplace for hazards that require PPE

- Provide appropriate PPE to employees at no cost

- Train employees on proper use, care, and limitations

- Ensure PPE fits properly and is maintained in usable condition

- Document training and update it when tasks or hazards change

If you skip any of these steps, you’re out of compliance and potentially liable if something goes wrong.

Bottom line: PPE is required anywhere serious hazards exist. And OSHA doesn’t just recommend PPE training, it mandates it.

Who Is Responsible for Buying PPE?

If PPE is required to perform the job safely, the employer must provide it at no cost to the employee. This includes everything from safety glasses and gloves to more specialized equipment like fall protection harnesses and respirators.

There are exceptions for certain items considered “everyday clothing,” like steel-toe boots or prescription safety eyewear, depending on the company policy and job role. But for job-specific, hazard-driven PPE, it’s the employer’s responsibility to supply compliant, quality gear.

Cutting corners on this not only puts workers at risk, but it also opens the company up to serious legal and financial consequences.

Who Ensures PPE Fits Properly?

PPE must fit the individual wearer, and the responsibility to ensure proper fit falls on the employer. Ill-fitting equipment leads to reduced protection and non-compliance.

Poorly fitting PPE can:

- Slip out of place

- Cause discomfort and distraction

- Fail to protect critical areas

- Be removed or avoided altogether

The solution is to provide a range of sizes and test fit before issuing the gear. Employers must also accommodate employees with different body types and specific needs; this includes providing options designed for women or smaller builds, and ensuring respirators are fit-tested per OSHA standards.

Who Is Responsible for Training Workers on PPE?

According to OSHA and nearly every major workplace safety standard, the employer must train workers on proper PPE use. That includes:

- When PPE is necessary

- What kind of PPE is required for specific tasks

- How to put it on, adjust, wear, and take it off safely

- How to care for, maintain, and dispose of PPE

- Limitations of the equipment

Safety managers and foremen are often tasked with delivering this training on-site, but the employer has the legal and ethical responsibility.

Training should happen before employees are exposed to hazards, during onboarding, or when tasks change. And yes, it needs to be documented.

How to Train Employees on PPE Use?

Practical PPE training needs to be simple, consistent, and specific to the worksite. The following script can be used as a baseline for formal training, toolbox talks, or jobsite refreshers.

Free PPE Training Script

“Today we’re reviewing Personal Protective Equipment, known as PPE. This includes any gear you’re required to wear to stay safe while doing your job.

Here’s what you need to know:

- PPE protects you from hazards that can’t be eliminated. If you’re cutting, grinding, lifting, kneeling, or exposed to chemicals or noise, PPE is there to minimize injury.

- The gear depends on the task. Gloves for cuts. Glasses for debris. Respirators for dust or fumes. Kneepads for repetitive floor work. We’ll walk through what’s required for each of your responsibilities.

- Don’t modify or remove PPE. Wear it as designed. If something doesn’t fit right or is damaged, immediately inform your supervisor. Gear that doesn’t fit doesn’t protect.

- Store your PPE properly. K and keep clean. Damaged or dirty equipment can fail. Report anything that looks worn out.

- Not wearing required PPE is a violation of company policy and OSHA regulations. It’s also a risk to your health and your team. If a task calls for PPE, it must be used, no exceptions.

Any questions?”

What PPE Training Records Does OSHA Require?

OSHA doesn’t just care that you trained your crew; they care how you prove it. Here’s what you need to document:

- Training date and time

- Topics covered (match these to hazard assessments)

- Names of attendees and trainer(s)

- Proof of understanding (verbal Q&A or written confirmation)

- Follow-up or retraining records if someone wasn’t following protocol

Keep these records for at least three years, or longer if your state has additional requirements. If you’re audited or inspected, this is your paper trail.

What Happens If You Skip PPE Training?

Here’s the reality: OSHA doesn’t just recommend PPE training, it requires it. If your jobsite has hazards that can’t be fully engineered out, PPE isn’t optional. And if PPE is needed, so is training.

OSHA can inspect your workplace with or without warning. If they find gaps in your PPE program, like missing documentation, improper fit, or employees working without gear, the fines stack up fast.

Common PPE Compliance Mistakes

- Not conducting a proper hazard assessment

- Failing to provide required PPE

- No documented training program

- Using damaged or ill-fitting gear

- Workers not wearing PPE when they should

The Cost of Non-Compliance

- Up to $16,550 per violation

- Up to $165,514 for willful or repeat offenses

- Additional fines or legal action if a preventable injury occurs

These updated amounts took effect January 15, 2025, and apply across all federal OSHA inspections. You could face these hefty fines if your training program isn’t solid, if you’re missing records, get caught with poor fits, or offer unclear instructions.

And remember: skipping training isn’t just a paperwork issue, it’s a safety issue. And it can cost far more than just a fine.

Conclusion

PPE training isn’t just a compliance box to check. It’s a chance to prevent real injuries and build a safer, more accountable workplace. When employees understand how PPE works and trust that their gear is made to fit and last, they’re far more likely to use it. Every job has risks. Training your team correctly ensures those risks don’t turn into accidents.

FAQ

Do I need to retrain workers on PPE?

Yes. You have to retrain if tasks change, if new equipment is used, or if someone shows they haven’t retained the training.

What if an employee refuses to wear PPE?

If an employee refuses to wear safety equipment, that’s a safety violation and needs to be addressed immediately. Consistent enforcement is essential.

Can employees bring their own PPE?

Yes, employees can bring their own PPE, but it must meet safety standards and be approved by the employer.

How do I document PPE training?

Document the training by use a sign-in sheet, keeping digital or hard copies, and including the date, topics covered, and the trainer’s name.

Is fit-testing required for all PPE?

Fit-testing is only for equipment like respirators. But ensuring proper fit for all PPE, especially gloves, glasses, and kneepads, is always necessary.