Key Takeaways

- OSHA fines rose in 2025: up to $16,550 per violation, $165,000 for willful/repeat ones.

- Fall protection and lack of training continue to dominate citations.

- Employees ignore safety rules when leadership treats them like a checklist.

- Rebuilding safety culture requires clarity, consistency, and example.

Why the Top OSHA Violations Still Matter in 2025

You already know that OSHA fines exist. You probably know the basics: fall protection, hazard communication, LOTO — those are the usual suspects. But here's the uncomfortable truth:

If you're still seeing the same violations in 2025, it’s not a paperwork issue. It’s a leadership one.

Every year, OSHA publishes its Top 10 Most Cited Violations. And every year, we see the same ones.

While we wait for the official report, early numbers shared at the 2025 NSC Safety Congress & Expo (yep, we were there) tell a familiar story: same violations, same risks, still not enough action.

Fall protection remains at the top for the 15th year in a row. Training violations are always close behind. That’s not just bad for your compliance record. It’s a sign that people are still getting hurt for preventable reasons.

It’s a wake-up call for every crew, contractor, and company to stop checking boxes and start protecting their people.

Did OSHA Fines Go Up In 2025?

Yes. In January 2025, OSHA increased its penalty rates:

- $16,550 per serious violation (up from $15,625)

- $165,532 per willful or repeat violation

- Daily penalties of up to $1,100/day for failure to abate hazards

These updates happen almost every year now, and they follow inflation, but the message is clear: If you keep cutting corners, it’ll cost you more not just in dollars, but in reputation, morale, and injuries.

And here’s the problem: OSHA isn’t just targeting big companies anymore. They’re showing up at smaller worksites, warehouses, and trades shops — and issuing real fines for things many employers still call “minor oversights.”

The 10 Most Cited Violations in 2025 (And Why They Happened)

1. Fall Protection (5914 violations)

The issue: Unprotected edges, roofs, and ladders are still leading causes of serious injuries and fatalities. Workers often skip harnesses or tie-offs on short-duration tasks, and supervisors may look the other way.

The fix:

- Train workers on when and how to use fall protection

- Require and enforce 100% tie-off policies

- Conduct regular site audits focused on edges and elevation hazards

PPE to use:

- Full-body harness with lanyard or SRL

- Anchor points rated to support 5,000 lbs

- Roof brackets, guardrails, and toe boards

2. Hazard Communication (2546 Violations)

The issue: Workers handle chemicals with no idea what they are or what they can do. SDS sheets are missing or inaccessible, and labeling is often overlooked.

The fix:

- Keep updated SDSs in a clearly labeled binder or digital system

- Label every container properly, including secondary containers

- Train employees on GHS symbols and proper chemical handling

PPE to use:

- Nitrile or chemical-resistant gloves

- Goggles or face shields for splash risks

- Respirators when working with volatile or dusty chemicals

3. Ladders (2405 Violations)

The issue: Workers use damaged ladders, place them at unsafe angles, or carry tools in hand while climbing. Most violations come from rushing.

The fix:

- Inspect ladders before every shift and tag damaged ones “Do Not Use”

- Train workers on the 4:1 ladder angle rule and 3-point contact

- Encourage the use of tool belts and staging gear

PPE to use:

- Slip-resistant boots

- Fall arrest systems when ladders are near leading edges

4. Lockout/Tagout (2177 Violations)

The issue: Employees work on machines without isolating energy sources. LOTO procedures are missing, vague, or ignored.

The fix:

- Create and post machine-specific LOTO procedures

- Provide LOTO kits for every work zone

- Train and retrain all affected employees annually

PPE to use:

- Insulated gloves for electrical LOTO

- Safety glasses while working near moving parts

- Arc-rated PPE when servicing high-voltage equipment

5. Respiratory Protection (1953 Violations)

The issue: Workers wear respirators without fit tests or medical clearance. Some don’t know if their respirator is right for the job or how to clean it.

The fix:

- Conduct annual fit testing for tight-fitting respirators

- Provide medical evaluations and proper cleaning protocols

- Match the respirator type (N95, P100, half-mask, etc.) to the hazard

PPE to use:

- Disposable N95s for dust

- Half-mask respirators for chemicals/fumes

- Full-face respirators for high exposure levels or eye hazards

6. Fall Protection Training (1907 Violations)

The issue: Even when fall gear is available, workers aren’t trained to use it. Training is sometimes skipped for short-term hires or subcontractors.

The fix:

- Require full fall protection training for any worker exposed to falls over 6 feet

- Provide practical demos, not just videos

- Document all training sessions and refreshers

PPE to use:

- Harness, lanyard, SRL

- Fall protection kits for temporary or short-term use

- Tool lanyards to prevent dropped objects

7. Scaffolding (1905 Violations)

The issue: Scaffold setups lack guardrails, planking is incomplete, or inspections are skipped. Falls and collapses are a major risk.

The fix:

- Have a competent person inspect scaffolds daily

- Use proper access ladders, not frames or cross braces

- Ensure guardrails and midrails are installed on all sides

PPE to use:

- Harness with scaffold-compatible fall arrest

- Hard hats

- Anti-slip footwear

8. Powered Industrial Trucks (1826 Violations)

The issue: Forklifts and pallet jacks are operated by workers with no certification or refresher training. Maintenance logs are often incomplete.

The fix:

- Provide OSHA-compliant certification training every 3 years or after an incident

- Keep daily inspection checklists near each vehicle

- Enforce safe speeds and visual/audible alerts in shared zones

PPE to use:

- High-visibility vests in mixed-use areas

- Steel-toe boots to prevent crush injuries

- Seatbelts (must be used!)

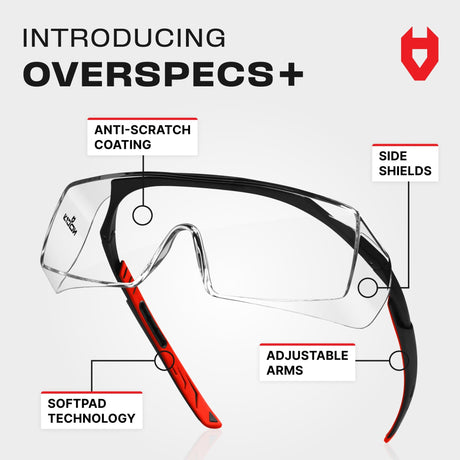

9. Eye and Face Protection (1665 Violations)

The issue: Sparks fly, dust swirls, and chemicals splash—but workers leave their eye protection behind, or wear scratched, ineffective gear.

The fix:

- Make safety glasses mandatory in all work areas

- Provide task-specific PPE: shaded lenses for welding, sealed goggles for chemicals

- Replace damaged PPE immediately

PPE to use:

- ANSI Z87.1-compliant safety glasses

- Chemical splash goggles

- Face shields for grinding or spray work

10. Machine Guarding (1239 Violations)

The issue: Machines run with guards removed for cleaning or access. Others are purchased without adequate guards or don’t meet OSHA minimums.

The fix:

- Never allow machines to operate with guards removed

- Retrofit older machines with proper guarding

- Train operators to recognize guarding requirements

PPE to use:

- Cut-resistant gloves for manual operation

- Safety glasses or face shields near rotating parts

- Ear protection in loud machine zones

“While progress has been made in many workplaces, the consistency in citation rankings year after year signals there is more work ahead,” said Lorraine Martin, NSC CEO. “The safety community must intensify our efforts to better protect workers and save lives. We can do this through robust training, updated metrics, high-hazard identification and control implementation, coupled with employee engagement and leadership accountability.”

Let’s be real: you can’t fine your way to a safer workplace. You can’t nag people into caring. And safety isn’t about being the strictest boss, it’s about being the most consistent one.

Every one of these violations has something in common: someone thought it wouldn’t matter this time. That’s not a documentation problem. That’s a cultural one.

If your team thinks the gear is “overkill,” or that the rules are just to keep inspectors happy, that’s a leadership problem. The truth is, most injuries happen in places where safety was technically in place, but not enforced.

How to Get Your Team to Take Safety Seriously

If your employees aren’t listening, it’s usually for one of three reasons: you aren’t setting an example, it feels like box-checking, or nobody is following up on it.

- You talk safety, but don’t walk it: if they see a foreman climbing a scaffold without fall protection, your training is meaningless. Model the behavior. Every time.

- It feels like box-checking, not real risk: people care more when they understand the “why.” Don’t just say “use a respirator.” Say: “That dust causes cancer. And we want you here in 10 years.”

- No one follows up: accountability doesn’t mean yelling, it means consistency. If someone skips the safety glasses once and no one corrects it, they’ll skip them again. And so will the next guy.

In a nutshell, you should lead by example. Make safety part of everyday conversation, not just orientation. Be consistent in enforcement, explain the “why,” and involve workers in hazard identification.

What Leadership in Safety Actually Looks Like

You don’t need a clipboard to lead safety. You need clarity, consistency, and a willingness to do what you ask others to do. That means:

- Auditing your own training gaps (start with the top 10 violations above)

- Making safety part of daily conversation, not just the annual meeting

- Following through on enforcement, even when it’s uncomfortable

- Giving your team tools that make safe behavior easier — like PPE that fits and doesn’t suck

Conclusion

OSHA fines are up, but the real cost is worse. Yes, $16,000 per violation adds up fast. Yes, OSHA shows up more than they used to. But here’s what doesn’t show up in a violation notice:

- The employee who can’t come back to work

- The family that’s left with medical bills

- The team that saw something happen and doesn’t trust leadership anymore

Remember: you can fix a citation. You can’t undo a serious injury. Use PPE, stay safe, and protect your pack.

FAQ

How often does OSHA update its fines?

OSHA adjusts its fines annually, typically in January, to keep up with inflation. In 2025, serious and other-than-serious violations rose to $16,550, and willful/repeat violations increased to $165,532.

Can small businesses get fined by OSHA?

Yes. OSHA inspects businesses of all sizes. In fact, smaller employers are often cited for missing basic protections, like training documentation or hazard communication, even if no incident occurred.

How does OSHA choose who to inspect?

OSHA inspections are often triggered by a workplace injury or fatality, employee complaints, referrals from other agencies, targeting of high-risk industries, and random emphasis programs.

Do I need written safety procedures for everything?

For many standards, yes. For example, lockout/tagout, hazard communication, fall protection, and machine guarding all require written plans, procedures, or training documentation.

What if my employee refuses to wear PPE?

Employers are legally responsible for enforcing PPE use. If an employee refuses, you must take disciplinary action just like with any other safety policy breach. Documentation matters here, too.

How do I prepare for an OSHA inspection?

Please have the following items ready: injury and illness logs (OSHA 300), safety training records, equipment inspection logs, written safety programs, SDS sheets and labels, and a calm and respectful point of contact.

What businesses fall under OSHA?

OSHA covers most private sector employers and their employees across various industries, including general industry, construction, maritime, and agriculture. Certain businesses, like those with specific federal agency oversight or those with only immediate family members as employees, may be exempt.