Key Takeaways

- All personal protective equipment (PPE) has a fixed lifespan determined by the manufacturer, and visual inspection alone is insufficient to guarantee safety.

- Employers in the US have a legal obligation under OSHA regulations (29 CFR 1910.132) to provide, maintain, and replace PPE when it is damaged or expired, at no cost to employees.

- Employees play a critical role in daily inspections, reporting defects, and ensuring expired or compromised PPE is removed from use.

- Maintaining a detailed PPE register that includes issue dates, manufacturer expiry dates, inspection history, and user assignments is essential for compliance and effective safety management.

- Proper storage, regular inspections, and proactive replacement protect employees, prevent costly incidents, and preserve the company’s reputation.

Personal protective equipment is essential for workplace safety, but every item has a limited service life. Relying solely on visual checks is dangerous, as materials such as plastics, textiles, adhesives, and metals naturally degrade over time.

Why PPE Expiry Dates Matter

Using expired or worn PPE is a serious safety risk. Materials degrade over time, and equipment can fail during critical moments, leading to injuries or fatalities. Beyond personal safety, expired PPE exposes employers to legal liability, OSHA citations, fines, and compensation claims.

The financial impact of workplace injuries due to expired PPE can be significant, including legal fees and higher insurance premiums. Maintaining up-to-date, compliant PPE demonstrates a commitment to worker safety and preserves your company’s reputation, building trust with employees, clients, and business partners.

Legal and Compliance Responsibilities in the US

In the United States, employers are primarily responsible for ensuring PPE is safe and within its service life. Under OSHA regulations (29 CFR 1910.132), employers must:

- Provide and maintain PPE: Ensure all equipment is in a sanitary, functional, and reliable condition.

- Supply PPE at no cost to employees.

- Establish inspection schedules: PPE should be inspected regularly, often annually, or more frequently for high-risk equipment.

- Replace defective or expired PPE immediately once identified.

Employees also have an important role in maintaining safety:

- Daily pre-use inspections: Workers should visually check their PPE before each shift.

- Reporting defects or expiry: Any damaged or expired items must be reported so they can be replaced before use.

PPE expiration in the US is guided by a combination of federal regulations, consensus standards, and manufacturer instructions:

- OSHA enforces the requirement that PPE must be “maintained in a clean and reliable fashion.” Expired equipment is considered defective and must be retired.

- ANSI standards provide guidance on design, durability, and service life for specific equipment types. Following manufacturer instructions is the “golden rule” for safe PPE use.

- NFPA standards apply to specialized roles, such as firefighting, where gear must be retired 10 years after the date of manufacture, regardless of appearance.

How PPE Lifespans Are Determined

Manufacturers typically define PPE lifespans in two ways:

- Maximum Lifespan (from manufacture): The total time from when the PPE is made. For example, a harness manufactured in 2024 with a 10-year maximum lifespan expires in 2034, even if it has never been used.

- Service Life (from first use): The time from when the PPE is issued to a worker. For example, a hard hat issued in 2024 with a 5-year service life must be retired in 2029, even if its maximum lifespan is longer.

Some mechanical or metal components may have an unlimited lifespan if regularly inspected and maintained, but this is rare. Always check manufacturer guidelines for each piece of equipment, and remember that recommended storage time before use effectively shortens usable service life.

Typical Lifespan of Common PPE in the US

PPE lifespans vary by type, manufacturer, usage intensity, and environmental conditions. Following manufacturer instructions is essential. General guidelines include:

- Hard Hats: Replace shells every 2–5 years depending on manufacturer instructions; suspension straps should be replaced annually. Replace immediately if impacted or damaged.

- Safety Footwear: Lifespan varies with use; daily wear in harsh conditions may require replacement every 3–6 months. With light use and proper care, footwear may last 1–2 years. Replace immediately if steel toes are exposed or soles lose traction.

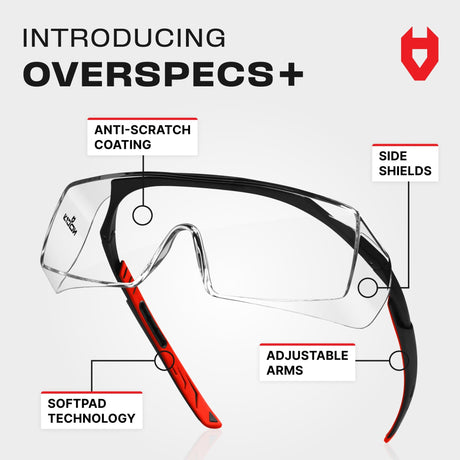

- Protective Eyewear: Safety glasses and goggles can last up to three years if not scratched or damaged. Replace immediately if lenses are compromised.

- Fall Protection (Harnesses & Lanyards): Maximum lifespan is typically 5–10 years from manufacture. Any harness involved in arresting a fall must be retired immediately. Inspections are critical to determine ongoing usability.

- Disposable Respirators (N95s): Usually have a “best before” date and expire three years after manufacture. They are typically single-use.

- Waterproof Workwear: High-quality waterproofs can last 3–5 years depending on frequency of use and exposure to harsh environments.

How Storage Affects PPE Lifespan

Proper storage is essential to preserving PPE integrity. Incorrect storage can degrade materials before they are even used. Best practices include:

- Store in a cool, dry location away from sunlight, chemicals, and extreme temperatures.

- Use clean, dry, and sealed containers or racks to avoid contamination or damage.

- Avoid overcrowding to prevent crushing, warping, or distortion.

- Follow manufacturer recommendations regarding pre-use storage times.

How to Effectively Manage PPE Replacement

A systematic approach ensures compliance and safety:

- Maintain detailed records: Keep a PPE register that tracks item type, date of issue, manufacturer expiry, user assignment, and inspection history.

- Schedule inspections: Conduct formal inspections annually or more frequently for high-risk PPE. Some equipment, like fall protection systems, requires inspection by a competent person every six months.

- Train employees: Provide training on daily visual inspections, proper storage, and reporting damaged or expired PPE. Workers must understand the importance of compliance.

- Have replacements ready: Do not wait until an item fails. Maintain a stock of replacement PPE to issue immediately when needed.

Conclusion

A PPE expiry date is a vital safety control. Managing the lifecycle of protective equipment is a fundamental part of an effective safety program that protects both employees and the business.

Expired or damaged PPE should never be used, regardless of appearance. Regular audits, proper storage, employee training, and proactive replacement are essential to maintaining a safe workplace.

FAQ

Who is responsible for replacing PPE?

Employers are responsible. OSHA mandates that they provide, maintain, and replace PPE at no cost to employees.

What records should be kept for PPE replacement?

Maintain a PPE register including item type, date of issue, manufacturer’s expiry date, inspection history, and scheduled replacement dates.

Do high-risk industries need more frequent replacement?

Yes. Industries like mining, chemical handling, and construction may require more frequent PPE replacement due to harsher conditions and accelerated wear.

Should I replace PPE that looks fine but is past its expiry date?

Absolutely. PPE must never be used beyond its manufacturer-specified lifespan. Material degradation is not always visible, and expired equipment is considered unsafe.