Key Takeaways

- The ANSI Z87.1-2020 standard ensures safety glasses are tested against real-world hazards, and compliance is often required by OSHA.

- The Z87+ marking signifies a higher level of protection, indicating the eyewear passed both high-velocity and high-mass impact tests.

- The US (ANSI Z87.1) and European (EN 166 or EN ISO 16321) standards use different testing methods and ratings that are not directly comparable.

- Starting in 2026, Europe transitioned to a stricter, more modern standard, EN ISO 16321, which better reflects today’s industrial risks.

What Does the ANSI Z87.1 Standard Actually Test For?

An ANSI Z87.1-2020 certification demonstrates that your eyewear has passed rigorous physical tests simulating real workplace hazards. These evaluations ensure your glasses perform when you need them most and meet the requirements set by OSHA and the ISEA for workplace eye protection.

One of the most critical evaluations is the high-velocity impact test, which simulates the danger of fast-moving debris common in grinding or machining operations. To pass, the glasses must remain fully intact without cracking, breaking, or allowing the lens to pop out of the frame. This test shoots a quarter-inch steel ball at the safety glasses at a speed of 150 feet per second — that’s over 100 mph.

Next is the high-mass impact test, which simulates a heavier falling object, like a tool. In this test, a pointed 500-gram (1.1 lb) weight is dropped from a height of 50 inches onto the eyewear. The frame and lenses must not shatter or break.

Beyond direct impacts, the standard includes other critical evaluations, including a lens retention test, optical clarity tests to prevent vision distortion, and a penetration test where a weighted needle with a total weight of 1.56 oz is dropped from a height of 50 in onto the lens.

What Is the Difference Between ANSI Z87 and Z87+?

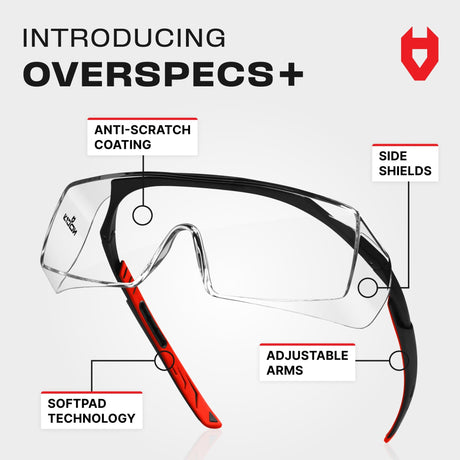

A standard Z87.1 marking indicates the eyewear passed the basic impact standard, specifically the drop ball impact test. The Z87+ marking signifies high-impact resistance. To earn the plus, the eyewear must pass the considerably tougher remaining tests. The higher rating then confirms the eyewear can withstand more significant and forceful impacts.

Another key difference in the Z87.1 vs Z87+ standards is coverage requirements, with Z87+ often mandating better side protection.

How Does ANSI Z87.1 Compare to the European EN 166 Standard?

The European Union and the United States rely on separate standards and regulatory frameworks to certify and test safety eyewear. The EN 166 standard is the older European counterpart to ANSI Z87.1. While both standards aim to ensure reliable eye protection, their testing methods and rating systems differ, meaning certifications are not directly interchangeable.

This difference is clear in impact testing. ANSI Z87.1+ uses a single high-velocity impact rating, while EN 166 relies on a tiered system for high-speed particles: F (low energy impact at 45 m/s), B (medium energy impact at 120 m/s), and A (high energy impact at 190 m/s). This structure allows protection levels to be matched to specific hazard assessments.

EN 166 also introduced optional markings not included in the base ANSI standard, such as K for resistance to surface damage from fine particles and N for resistance to fogging. These usability features became widely adopted in Europe. When comparing EN 166 vs ANSI Z87.1, eyewear should always be selected based on regional regulatory requirements, not assumed equivalency.

Although both standards address high-velocity impact, their rating structures and test parameters differ, and compliance with one does not automatically satisfy legal requirements in the other without separate certification.

What Is The New EN ISO 16321 Standard?

To keep pace with modern materials, technologies, and workplace risks, safety standards must evolve. After nearly 20 years of use, EN 166 has been officially replaced by EN ISO 16321, with the transition completed at the end of 2025.

One of the biggest changes in EN ISO 16321 is stricter and more detailed impact testing. The basic impact test now uses a 66.8 g steel ball, up from the 43 g ball used in EN 166, better reflecting real-world industrial hazards.

Additional updates include a high-mass impact test similar to ANSI Z87.1, signaling a move toward global harmonization. The standard also doubles thermal exposure testing to 120 minutes, requires larger protective coverage, and introduces updated headform sizes based on EN ISO 18526-4:2020 to better represent the global workforce.

These upgrades make EN ISO 16321 a more comprehensive replacement for EN 166 and bring its overall testing philosophy closer to ANSI Z87.1, while still maintaining distinct certification requirements.

Note: You do not need to immediately replace existing EN 166-compliant eye protection. EN 166:2001 is still valid for existing, certified products, likely until 2030 at the latest. When replenishing stock, you can choose to transition to products certified to the new EN ISO 16321 standards.

How Does ANSI Z87.1 Compare to the European EN ISO 16321 Standard?

Both ANSI Z87.1 vs EN ISO 16321 are designed to protect vision through rigorous impact testing, but EN ISO 16321 replaces the older EN166 standard with stricter, more detailed requirements. ANSI Z87.1 uses a single high-impact designation (Z87+) for eyewear tested against high-velocity and high-mass impacts.

EN ISO 16321, by contrast, requires testing with a steel ball, includes a high-mass impact test, and mandates larger protective surfaces to better shield the eyes and face. It also incorporates updated headform sizes to represent the global workforce and uses multiple performance classifications to reflect different hazard levels.

These changes make EN ISO 16321 closer in testing philosophy to ANSI Z87.1 than EN166, emphasizing real-world impact scenarios, heavier projectiles, broader coverage, and detailed classifications.

While the standards are still not interchangeable, EN ISO 16321 provides a more modern, globally harmonized benchmark that aligns more closely with US requirements and improves protection for a wide range of workplace hazards.

Conclusion

Safety ratings reflect real testing, not just markings on a frame. In the US, ANSI Z87.1 remains the active standard, with Z87+ indicating high-impact protection. In the EU, the older EN166 standard has been replaced by EN ISO 16321, which uses stricter and more detailed testing requirements.

Because these standards are not interchangeable, eyewear should always be selected based on the current regulations in your region and the hazards involved. Choosing correctly is essential for protecting vision and maintaining a safe workplace.

FAQ

What’s the difference between the ANSI Z87.1 and the EN ISO 16321 impact test?

The main difference is in their classification. ANSI Z87.1 uses a single high-impact rating (Z87+). EN ISO 16321, which replaced EN166 in the EU, uses more detailed impact testing, including higher-mass projectiles, expanded coverage requirements, and multiple performance classifications.

Is EN ISO 16321 equivalent to ANSI Z87.1?

No. While EN ISO 16321 moves closer to ANSI Z87.1 in testing philosophy, the standards are not equivalent or interchangeable and require separate certification.

Is EN ISO 16321 the same as EN166?

No. EN ISO 16321 is the newer standard that replaces EN166. It introduces stricter impact testing, longer thermal exposure tests, and larger protective areas.

Does Z87+ mean the eyewear meets EU standards?

No. Even if the eyewear meets high-impact requirements, Z87+ only certifies compliance with ANSI Z87.1. EU compliance requires certification under EN ISO 16321.

Can safety goggles be certified under ANSI Z87.1?

Absolutely. Safety goggles, like safety glasses, are tested and must meet the same regional standards to ensure adequate eye protection.

Is EN 166 still valid?

Yes, EN 166:2001 is still valid for existing, certified products. As of 2026, no new certifications can be issued for this standard, but existing products with valid EN 166 certificates can still be sold until those certificates expire (potentially up to 2030).