Contents

Key Takeaways

- Lens color is a functional tool for safety, not an aesthetic choice. It improves visibility by managing different types of light and enhancing contrast.

- Clear lenses are the standard for indoors and night work, providing maximum visibility and true color perception for general-purpose impact protection.

- Gray lenses are the best all-around choice for bright sun and outdoor work, as they reduce glare and eye strain without distorting colors.

- Amber, yellow, and orange lenses boost contrast in low light, hazy, or overcast conditions, but they can alter color perception and are unsuitable for jobs like electrical wiring.

- Specialty lenses are required for high-risk jobs, such as green shades for tasks near welding or cobalt blue lenses for furnace and molten metal work.

- UV protection keeps your eyes safe from invisible rays, while VLT controls brightness and glare, so choosing the right combination ensures both safety and visual comfort.

Why Does Lens Color Even Matter?

Choosing the right safety glasses lens color is a critical decision that directly impacts performance and safety. A lens's color isn’t for looks; it’s an engineered feature designed to optimize vision in specific environments.

Different lens colors are designed to filter specific wavelengths of visible light. This practical tool manipulates how you see your work area.

A colored lens filters light to reduce glare, enhance contrast, and improve depth perception. This allows workers to see hazards more clearly, perform detailed tasks more accurately, and reduce eye strain over a long shift.

Using the wrong lens for the conditions can be dangerous, as it can mask hazards, distort critical color-coded signals, or cause eye fatigue that leads to mistakes and accidents.

Does Lens Darkness Equal UV Protection?

Many people assume that darker lenses automatically protect their eyes from the sun. In reality, UV protection and lens darkness are completely separate. UV rays are invisible, so no matter how dark a lens looks, it may not block harmful radiation.

UV protection comes from either the lens material (like polycarbonate) or a clear UV coating applied to the lens. Polycarbonate lenses naturally block nearly all UVA and UVB rays, while glass or plastic lenses may require a UV400 coating for full protection.

Even completely clear lenses can provide full UV protection, which is why construction workers, lab technicians, and cyclists often wear transparent eyewear outdoors. The darkness of a lens is for reducing glare and improving comfort; it does not contribute to eye safety.

What Is Visible Light Transmission?

Visible Light Transmission, or VLT, is the percentage of visible light that passes through a lens. VLT directly affects brightness, glare, and visual comfort. A low VLT lets less light in (a darker lens), while a high VLT lets more light in (a lighter lens).

Understanding VLT is essential for choosing the right lens for your environment. Too dark a lens in low light can hide hazards, while too light a lens in bright sun causes squinting, fatigue, and eye strain.

Here are standard VLT ranges and the conditions they are best suited for:

- 5–19% VLT (Very Dark): Extreme sun, snow, water, or high-glare outdoor work.

- 20–50% VLT (Medium): Bright sun, everyday outdoor tasks like construction, roofing, or driving.

- 50–80% VLT (Light): Overcast or low-light conditions, early morning or late afternoon work.

- 80%+ VLT (Very Light/Clear): Nighttime, indoor, or inspection work where color accuracy is critical.

Matching lens darkness to lighting conditions ensures both safety and comfort. Professionals often keep multiple VLT options on hand for different tasks.

What Is the Best Lens for My Work Environment?

Match the lens to the light. This guide covers the most common lens colors and their ideal applications based on your primary work environment:

For General Indoor & Night Work

Clear lenses: Clear is the standard and most common lens for safety glasses. It is the best choice for indoor, low-light, or nighttime work because it allows the maximum amount of light to pass through.

This ensures the highest visibility and true color perception, which is important for general-purpose impact protection in environments like construction sites, laboratories, fabrication shops, and warehouses. It is also ideal for supervisors or workers who require clear eye contact for communication.

For Bright Sun & Outdoor Work

Gray, smoke lenses: Gray lenses are the best and most popular option for working in bright, sunny conditions. They reduce overall brightness and glare just like standard sunglasses, but critically, they do so without distorting color perception. This ensures that safety signs, traffic signals, and other color-coded indicators remain accurate.

Brown, copper lenses: These lenses also perform well in bright light, but they offer the added benefit of enhancing contrast and depth perception, especially against green and blue backdrops like foliage, grass, and sky. Choose these over gray lenses if your work involves judging distance or spotting details against natural landscapes.

For Low Light, Fog, or Hazy Conditions

Amber, yellow, orange lenses: These bright lenses are ideal for low-light situations like dawn, dusk, overcast days, or dimly lit indoor areas. They work by blocking blue light, which can create a hazy effect, making the environment appear brighter and significantly increasing contrast and depth perception.

Remember that these lenses significantly alter color perception. Avoid them for jobs that require accurate color recognition, such as identifying color-coded electrical wires or safety indicators.

For Specific Indoor Lighting

Blue lenses: Blue lenses are a specialty option designed to reduce the harsh yellow glare from sodium vapor lighting. This type of lighting is sometimes found in older warehouses or manufacturing facilities, and blue lenses can enhance contrast and comfort in these specific conditions.

Pink, vermilion lenses: Pink or vermilion lenses effectively reduce glare from fluorescent and halogen lighting. By filtering certain light wavelengths, they can sharpen visual acuity, reduce eye strain, and improve focus during detailed indoor inspection tasks.

What About Color Lenses for High-Risk Jobs?

Some industrial tasks produce hazardous optical radiation that requires specialized protection beyond standard safety glasses.

Welding & Cutting

Green shade lenses: Green lenses with a specific shade number (e.g., Shade 3.0 or 5.0) are required for tasks such as torch brazing and cutting, or for individuals working near welding operations. These lenses are engineered to filter out the hazardous infrared (IR) and ultraviolet (UV) radiation produced by these high-heat processes, which can cause severe and permanent eye damage.

Note that these are distinct from general-purpose IR-filtering lenses, which may not provide the necessary UV protection or visible light filtering required for welding tasks. Always select eyewear based on the specific shade number required by OSHA for your operation.

These are not the same as general-purpose green sunglasses and must never be used for direct welding, which requires a proper welding helmet.

Furnace Work & Molten Metal

Cobalt blue lenses: These highly specialized lenses are used in the molten metal industry, including mill and foundry work. They are designed to filter the intense yellow and orange light (known as the “sodium line”) emitted from molten materials. This allows workers to see the process more clearly while protecting their eyes from extreme radiant heat and harmful light.

Are There Any “All-in-One” Solutions?

While carrying two pairs of glasses (one clear, one tinted) is often the safest bet, some lens technologies offer a compromise for workers who frequently move between different lighting conditions.

Indoor/Outdoor Lenses

An I/O lens has a very light tint, often combined with a subtle mirror finish. Its purpose is to reduce glare when moving from an indoor area to a bright outdoor one without being too dark to see indoors. This makes it a practical option for forklift operators or shipping and receiving personnel.

However, it is a compromise. This convenience comes at the cost of optimal vision; some workers may experience reduced clarity indoors and insufficient glare protection in full sun, potentially masking hazards.

Photochromic (Transition) Lenses

Photochromic lenses automatically darken when exposed to UV light (like sunlight) and lighten indoors. This technology eliminates the need to switch glasses.

The primary disadvantage is the transition speed; the change can take up to a minute, which may leave a worker temporarily unable to see clearly when moving from a dark to a bright area, or vice versa.

Polarized Lenses

Polarized lenses feature a special filter that blocks the intense, horizontally reflected glare bouncing off flat surfaces like water, pavement, snow, or polished metal. This significantly reduces eye strain and fatigue, making them ideal for road crews, drivers, and anyone working near water.

The main drawback is that polarized lenses can make it difficult or impossible to read some LCD and LED digital screens, such as those found on smartphones or heavy equipment.

What Should You Consider When Buying Tinted Glasses?

Follow these three steps to select the right safety glasses for your needs.

1. Assess your environment: First, analyze your primary work location. Ask yourself: Is it mostly indoors or outdoors? Is the light consistently bright, dim, or does it vary throughout the day? The answers will help you narrow down the appropriate lens colors.

2. Identify the hazards: Next, consider the specific risks associated with your job. Do you face flying debris from cutting or grinding (requires a Z87+ rating)? Is there a risk of chemical splash (requires goggles marked with D3)? Or are you exposed to radiant energy from welding (requires a specific shade number)? Match the eyewear’s features to the hazards.

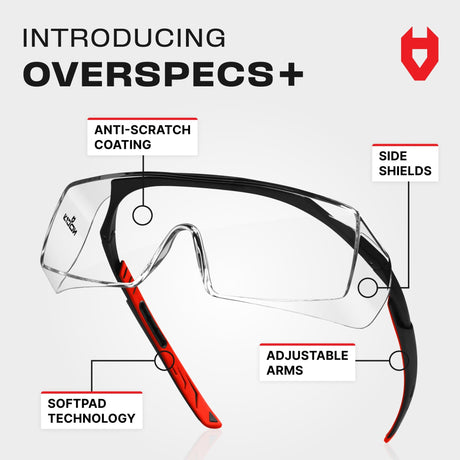

3. Prioritize fit and comfort: The most effective safety glasses are the ones that are actually worn. Protection is useless if the eyewear is sitting on a workbench because it’s uncomfortable. Look for features like lightweight frames, non-slip nose pads, and options for larger head sizes (XL frames) to ensure a secure fit that can be worn all day without causing pressure points.

What Other Safety Features Should I Look for in Glasses?

Lens color is only part of the picture when it comes to safety eyewear. Coatings and markings provide critical information about durability, performance, and protection levels, helping you choose glasses that match your specific work environment.

Lens Coatings

Coatings enhance the functionality of your lenses:

- Anti-fog: Prevents fogging in humid conditions or when wearing masks.

- Anti-scratch (hard coating): Increases durability and extends lens life.

- Mirrored coatings: Reflect extra sunlight to reduce glare in bright outdoor conditions.

Impact Protection

All occupational safety eyewear must meet the ANSI Z87.1 standard. Look for:

- Z87: Standard impact protection.

- Z87+: Higher-velocity and high-mass impact protection, ideal for jobs like grinding or using power tools.

Splash and Dust Protection

Some glasses also guard against liquids and particles, marked with “D” ratings:

- D3: Protection from droplets and splashes.

- D4: Protection from general dust.

- D5: Protection from fine dust or tiny particles.

Choosing glasses that match the right combination of coatings and markings ensures both safety and longevity. For instance, a construction worker might need Z87+ lenses with anti-scratch coatings, while an inspector in a dusty warehouse may prioritize D5 dust protection.

Conclusion

Selecting the right safety glasses lens color is a crucial step in professional eye safety. It’s not about fashion; it’s about using the correct tool to enhance your vision, reduce eye strain, and protect yourself from workplace hazards.

A clear view of your work environment helps prevent mistakes and keeps you safe. Armed with this knowledge, you can now select the right color lens as the specialized tool it is: one that enhances your vision and ensures your safety on the job.

FAQ

What is the difference between UV rating and VLT in sunglasses?

UV protection is about long-term eye health, while VLT is about day-to-day comfort and performance. You need both to work safely. For example, a construction worker on a bright day benefits from a low VLT lens with UV protection to reduce glare. An inspector in a dim warehouse needs a high VLT lens with UV protection to see details clearly without straining their eyes.

Can I just use my regular sunglasses for work?

No. Regular sunglasses are not rated for impact protection and will not protect your eyes from common workplace hazards like flying debris. For work applications, you must use eyewear that is clearly marked as compliant with the ANSI Z87.1 standard.

What lens color is best for driving?

Gray is an excellent choice for driving because it reduces sun glare and overall brightness without distorting colors, which is essential for accurately seeing traffic signals and signs. Brown lenses are also a good option, as they can enhance contrast and depth perception.

Do I need polarized lenses on my safety glasses?

Polarized lenses are highly recommended if you work outdoors around highly reflective surfaces like water, concrete, snow, or polished metal. They are the most effective option for cutting reflected glare and reducing eye fatigue. However, be aware that they can make it difficult to view some digital screens.

Can clear lens safety glasses protect your eyes from the sun?

Yes. Clear lenses can provide 100% UV protection. Polycarbonate lenses or lenses with a UV400 coating block nearly all harmful rays, even without any tint. This is especially useful for indoor work, inspections, or low-light environments where visibility and color accuracy are critical. Workers in these settings don’t sacrifice safety—they get maximum clarity while blocking UV exposure.

1 comment

Great article! Lots of useful information! Thank you!

Are the orange over-glasses safety glasses safe for nighttime driving when it’s pitch black outside?

Do you make a yellow over-glasses safety glasses?

Which is better for nighttime driving—orange or yellow when it’s pitch black outside and you have to watch for animals and objects on the road?