Contents

Key Takeaways

- ANSI standards focus on North American workplaces, while CE is required in Europe.

- ANSI certification is voluntary but widely respected in the US, often used as a benchmark for quality.

- CE testing can include impact, ergonomics, and chemical resistance, making it relevant even outside the EU.

- Testing methods differ significantly, so you can’t directly convert ratings between ANSI and CE.

- Sourcing PPE with dual certification can simplify compliance and safety across multiple regions.

- Proper documentation and supplemental testing can help demonstrate due diligence and reduce liability.

What Do ANSI and CE Marks Actually Mean?

ANSI standards are for the US and North America, created through consensus. CE standards, on the other hand, are mandatory in EU countries.

The American National Standards Institute is a private non-profit that develops voluntary standards across industries, including PPE. When a product carries ANSI certification, it has been tested against rigorous performance benchmarks for things like cut resistance, impact protection, and abrasion durability.

Using gear that meets ANSI standards ensures compliance with common industry expectations, even if it’s not legally mandated.

On the other hand, CE, or Conformité Européenne, represents compliance with European Union safety, health, and environmental regulations. Unlike ANSI, CE is legally required for many PPE products sold in Europe.

That said, CE is increasingly relevant outside Europe, especially for multinational operations or imported PPE. Many CE-certified products include protections that ANSI doesn’t evaluate, such as impact-rated knee pads, chemical splash resistance, or ergonomic features, which may be valuable in US workplaces.

Also, while ANSI focuses on verifying performance through independent testing, CE places legal responsibility on the manufacturer to ensure the product meets the essential requirements. Both marks communicate safety and quality, but the protections they cover, testing methods, and legal implications differ. Understanding what each mark actually certifies is critical for making informed decisions.

Knowing the intended market and geographic scope of your PPE helps workers and companies match the right gear to the hazards they face. It also prevents situations where equipment is chosen based solely on a number or letter rating without understanding what was actually tested.

What Is Legally Required In The US?

ANSI certification in the US is voluntary, but it is widely recognized and often expected by employers. Many companies require ANSI compliance in contracts, safety programs, and audits. Most importantly, OSHA frequently adopts or references ANSI standards in its own regulations, which makes those specific ANSI standards legally enforceable and therefore required.

And even when it’s not required, ANSI-certified equipment provides independent verification of performance, giving both employers and workers confidence that the PPE meets a consistent standard.

The distinction matters: CE is legally binding where it applies, while ANSI is a strong performance benchmark that demonstrates commitment to safety, even without legal enforcement.

Who Is Responsible For Testing PPE?

The way PPE is tested differs between ANSI vs CE, reflecting their distinct philosophies.

ANSI certification typically involves independent, accredited laboratories performing rigorous testing. Third-party verification ensures that the product consistently meets the standard’s performance requirements. For workers and procurement teams, this independent evaluation provides confidence in the product’s reliability.

CE certification is generally self-certified by the manufacturer, although some high-risk PPE requires a Notified Body to participate in conformity assessment. The manufacturer must maintain detailed technical files, test results, and a Declaration of Conformity showing the PPE meets applicable EU directives. CE emphasizes manufacturer accountability rather than independent verification.

What Does PPE Testing Look Like in Practice?

Imagine two pairs of gloves, one tested under ANSI/ISEA 105 in the US, and the other under EN388:2016 in Europe. Both claim to be “cut-resistant,” but how they’re tested, and what those results mean, are completely different.

In the ANSI test, a straight blade moves across the material under increasing weight until it cuts through over a 20mm distance. The amount of force needed determines the rating, from A1 (lowest) to A9 (highest). This gives a clear idea of how much pressure it takes to cut the glove in a real-world motion like pulling a blade across fabric.

The CE test, on the other hand, often uses a rotating circular blade under constant pressure. It measures how many cycles it takes to cut through the material. However, highly cut-resistant fibers can dull the blade, making the result unreliable. In those cases, the CE standard switches to a TDM-100 test (ISO 13997), similar to the ANSI method, and assigns a letter rating from A to F.

While the methods seem close, they’re not directly interchangeable. An ANSI A5 glove isn’t automatically the same as a CE Level E. The materials, blade motion, and pressure all differ, so comparing the numbers one-to-one can mislead workers or procurement teams.

That’s why many manufacturers now provide dual test data, showing both the ANSI and CE results side by side, so buyers can see how each standard rates the same product.

How To Read ANSI vs CE Markings?

The markings printed or engraved on your PPE are a code that tells you how your gear was tested, where it’s approved for use, and what protections it offers. Understanding these markings helps you choose the right equipment and explain your selection during audits or safety checks.

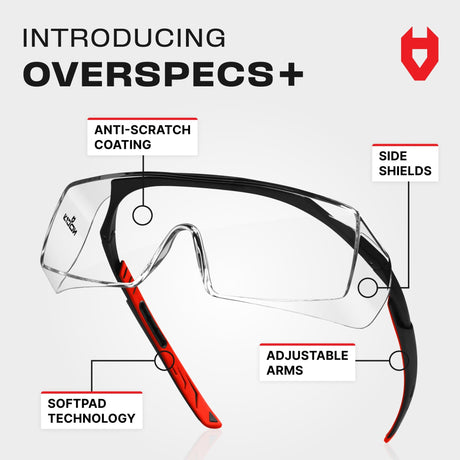

For ANSI-certified PPE, markings often include the ANSI standard number and year (like ANSI/ISEA 105-2016 for gloves or ANSI/ISEA Z87.1-2020 for eye protection), along with a performance rating such as “A5” for cut resistance or “Z87+” for impact-rated eyewear. These markings show exactly which version of the US standard the gear was tested to and what protection level it achieved.

For CE-marked PPE, the label usually includes the CE logo, followed by a four-digit number if a Notified Body was involved in certification. It may also list the EN standard reference (like EN388:2016 for gloves or EN166 for eye protection) and a series of pictograms and numbers that represent performance in different tests, for example, abrasion, cut, tear, puncture, or impact resistance.

Unlike ANSI markings, CE markings are part of a legal traceability system. They link back to a Declaration of Conformity and the manufacturer’s technical documentation. If you’re ever questioned during an inspection, having that link is what proves the product’s compliance.

What Are Best Practices for Multinational Companies?

Sourcing PPE for teams across regions comes down to consistent protection and legal compliance. Prioritize products that carry both ANSI and CE certifications, but also check the specific metrics behind each rating, since numbers or letters are not always directly comparable. Work with suppliers who can provide detailed technical datasheets and lab reports.

For multinational teams, standardizing dual-certified PPE reduces confusion and ensures workers are protected according to local requirements. Keep a centralized PPE matrix mapping certifications, protection types, and locations, so procurement and safety teams can make informed decisions efficiently. Bulk agreements with trusted manufacturers also help maintain consistency across sites.

What If Only One Certification Is Available for Required PPE?

When only one certification is available, a careful risk assessment and documentation approach is essential. Evaluate the hazards workers face and the protections the PPE provides.

For instance, ANSI-only gloves may meet US cut-resistance standards but lack CE-tested impact padding. In such cases, supplement with additional gear or administrative controls.

Document your rationale clearly: what hazards are addressed, where gaps exist, and how they are mitigated. Communicate limitations to your team so everyone understands how to use the equipment safely. Regularly review regulatory updates, especially for chemical, fall, or industrial PPE, to ensure ongoing compliance.

What Are the Legal Risks of Using PPE With The Wrong Certification?

Using PPE with only CE certification in the US carries potential legal and compliance risks.

OSHA and other regulators do not automatically recognize CE as proof of meeting local standards like ANSI. Relying solely on CE documentation could result in fines, citations, or liability if an injury occurs.

Employers can reduce risk by taking proactive steps. Keep the CE Declaration of Conformity and test reports on file, and create a mapping of CE results to ANSI or other US metrics. Where gaps exist, add supplemental protection, conduct site-specific risk assessments, or obtain third-party verification from a US-recognized lab.

Maintaining detailed documentation, including supplier statements, lab reports, and internal evaluations, demonstrates due diligence. It shows regulators and auditors that PPE was carefully evaluated for the hazards present, even if it wasn’t originally tested to US standards.

Whenever possible, sourcing dual-certified PPE simplifies compliance, but these steps provide a defensible approach if CE-only gear must be used.

Conclusion

Next time you grab gloves, knee pads, or glasses, look beyond the marks. ANSI and CE measure safety differently, and both tell an important story. Understanding the metrics behind each standard and knowing the law helps you make decisions that truly protect on the job.

FAQ

What does ANSI stand for?

ANSI is the American National Standards Institute. It develops voluntary consensus standards for safety and performance in US industries.

What does CE stand for?

CE, or Conformité Européenne, shows that a product meets EU rules for health, safety, and environmental protection.

Can PPE have both ANSI and CE marks?

Yes. Dual-certified PPE ensures compliance across regions, but ratings are based on different tests and aren’t directly comparable.

If my PPE has a CE mark, can I legally use it in the US?

You can use it, but OSHA may not recognize it as compliant. Documentation or third-party tests help show equivalent protection.

Do CE and ANSI test for the same hazards?

Not exactly. ANSI focuses on core performance like cut, impact, and penetration resistance, while CE often includes additional protections such as chemical resistance, ergonomics, and material durability.