Key Takeaways

• A Personal Fall Arrest System (PFAS) is made up of five critical elements: anchorage, body support, connecting device, descent and rescue, and education.

• All fall protection equipment must be inspected before every use for damage, defects, or improper function.

• A worker whose fall has been arrested remains at serious risk until they are safely rescued.

• Use passive fall protection whenever possible; when hazards can’t be eliminated, active systems like PFAS must be used correctly as a complete ABCDE system.

What Are the ABCDEs of Fall Protection?

The ABCDEs of fall protection are a commonly used framework for remembering the five fundamental components of a complete fall protection system: anchorage, body support, connecting device, descent and rescue, and education.

Individually, none of these components can adequately protect a worker from a fall. When properly selected, inspected, and used together as an integrated system, they form a compliant and effective Personal Fall Arrest System (PFAS).

A: What Is an Anchorage?

An anchorage is the secure point of attachment for the entire Personal Fall Arrest System. Common anchorages include structural steel (such as I-beams), engineered anchor points, or approved structural members. Anchorage points must always be independent of the worker’s means of support.

According to OSHA, anchorages used for fall arrest must be capable of supporting at least 5,000 pounds (22.2 kN) per worker attached, or be designed, installed, and used under the supervision of a qualified person with a safety factor of at least two.

More practically, an anchorage connector is the component that joins the connecting device (such as a lanyard or SRL) to the anchorage. Common examples include cross-arm straps, beam anchors, D-bolts, and concrete anchors.

Anchorage placement is critical to worker safety. The preferred anchorage location is directly overhead, which minimizes free-fall distance and helps prevent a dangerous swing fall. Swing falls occur when the anchorage is positioned laterally from the worker, causing pendulum-like motion that can result in serious secondary impact injuries.

B: What Is Body Support?

The only acceptable form of body wear for fall arrest is a full-body harness. Body belts are prohibited for fall arrest applications.

A full-body harness is designed to distribute fall forces across the strongest parts of the body, including the thighs, pelvis, chest, and shoulders. This distribution significantly reduces the risk of internal injury during fall arrest.

Key Feature: The D-Ring

The dorsal (back) D-ring, located between the shoulder blades, is the correct attachment point for fall arrest systems. Other D-rings, such as side or frontal D-rings, are intended for work positioning, ladder climbing, or rescue, not fall arrest unless specifically designed and approved for that use.

Post-Fall Safety Considerations

After a fall has been arrested, suspension trauma becomes a serious concern. Devices designed to mitigate suspension trauma include:

• Trauma straps: Allow the worker to stand in the harness to relieve pressure on the femoral arteries.

• Integrated relief systems: Some harnesses include built-in suspension relief features, sometimes referred to as a “chair-in-the-air” configuration, allowing the worker to assume a seated position until rescue.

C: What Is a Connecting Device?

The connecting device links the full-body harness to the anchorage connector. The two most common types are shock-absorbing lanyards and self-retracting lifelines (SRLs).

Shock-Absorbing Lanyards

Shock-absorbing lanyards include an internal energy absorber designed to deploy during a fall, typically extending up to 3.5 feet. This deployment reduces arresting forces on the worker to OSHA-acceptable limits.

These devices generally require greater fall clearance, often 18.5 feet or more, depending on worker height, anchor location, and lanyard length.

Self-Retracting Lifelines (SRLs)

SRLs allow greater mobility while significantly reducing free-fall distance. Their braking mechanisms engage rapidly, often arresting a fall within 24 inches or less, making them ideal for work environments with limited clearance.

Under ANSI Z359:

• Class 1 SRLs must be anchored at or above the dorsal D-ring.

• Class 2 SRLs are designed and tested for anchorage below the D-ring and may be approved for Leading Edge work, where the lifeline could contact a sharp edge during a fall.

D: What Is Descent and Rescue?

Descent and rescue addresses what happens after a fall has been successfully arrested. Without a prompt and practiced rescue plan, a suspended worker remains in serious danger due to suspension trauma, restricted circulation, and environmental exposure.

A proper rescue plan prioritizes speed, coordination, and minimizing risk to rescuers.

Types of Rescue

- Self-Rescue: The worker can climb or return to a safe surface independently.

- Assisted Self-Rescue: Co-workers assist using ladders, lifts, or rescue devices while the fallen worker can still help.

- Mechanically Assisted Rescue: When the worker cannot assist, rescuers use mechanical equipment such as aerial lifts or pre-engineered rescue systems. A secondary lifeline is typically attached before disconnecting the worker from impacted equipment.

E: What Is Education?

Education is the element that ensures every part of the ABCDE system is selected, inspected, and used correctly.

OSHA requires that workers exposed to fall hazards receive training from a competent person, covering:

• Recognition of fall hazards

• Proper inspection of equipment

• Correct use and limitations of PFAS components

• Rescue procedures

Even the highest-quality equipment cannot protect a worker who does not know how to use it properly.

Active vs. Passive Fall Protection Systems

Fall protection systems are generally categorized as active or passive, based on how much worker involvement is required for them to be effective. Most comprehensive fall protection programs use a combination of both.

What Is Passive Fall Protection?

Passive fall protection systems protect workers without requiring any action or special behavior once installed. These systems are always on and do not rely on worker decisions to function.

Common examples include:

- Guardrails

- Covers over floor openings

- Permanent stair systems

- Fixed parapet walls

Because passive systems eliminate the fall hazard entirely, OSHA considers them the preferred method of fall protection whenever feasible. They also reduce the risk of human error, which is a major factor in fall incidents.

What Is Active Fall Protection?

Active fall protection requires the worker to take deliberate action, such as putting on equipment and connecting to an anchorage, to be protected.

Examples include:

- Personal Fall Arrest Systems (PFAS)

- Travel restraint systems

- Positioning systems

- Controlled descent devices

The ABCDEs discussed in this article primarily apply to active fall protection systems, particularly PFAS. While active systems are highly effective when used correctly, they depend heavily on proper training, inspection, and consistent use.

Whenever possible, passive systems should be used to eliminate fall hazards. However, many jobs, such as roofing, steel erection, tower work, and maintenance, cannot rely on passive protection alone. In those cases, active systems become essential, making training and system integrity critical.

What Other Gear Complements a Fall Arrest System?

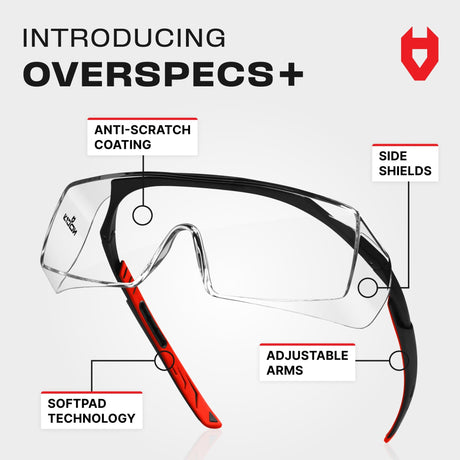

While the ABCDEs form the core of fall protection, additional PPE is critical for overall safety when working at heights. Head protection, such as hard hats or safety helmets, is essential due to the constant risk of falling objects and secondary impacts.

What Should You Consider When Buying Gear?

• System Compatibility: Components from different manufacturers should only be used together if they are designed and tested for compatibility. Incompatibility can lead to failures such as snap-hook roll-out.

• Regulations and Standards: Equipment must meet OSHA requirements. ANSI standards, while voluntary, establish best-practice performance benchmarks.

• Application and Environment: Consider exposure to dirt, oil, moisture, chemicals, temperature extremes, and job-specific hazards.

How Do I Know My Gear Is Safe to Use?

All PFAS components must be inspected before each use. Inspection logs for harnesses, lanyards, and SRLs should be completed and retained for the service life of the equipment.

Key don’ts:

- Don’t use fall protection gear for material lifting

- Don’t attach lanyards to guardrails unless specifically rated

- Don’t tie knots in web lanyards, as this can reduce strength by up to 50%

Conclusion

Effective fall protection depends on using a complete system, not individual components. The ABCDEs work together to reduce risk when working at height. When hazards can’t be eliminated with passive protection, a properly selected, inspected, and trained PFAS is essential for keeping workers safe.

FAQ

At what height is fall protection required?

OSHA requires fall protection at 4 feet for general industry and 6 feet for construction.

Can I use a body belt for fall arrest?

No. Only a full-body harness is approved for fall arrest.

How strong does an anchorage need to be?

At least 5,000 pounds per worker, or designed with a safety factor of two under a qualified person.

What is the difference between active and passive fall protection?

Passive fall protection prevents falls without requiring worker action, such as guardrails or covers. Active fall protection requires workers to wear and correctly use equipment like harnesses and lanyards to arrest a fall if one occurs.